The tensile strength test was performed as per the procedure explained in the chapter 2 and the results were tabulated as shown in table 3.11. The properties that were evaluated as a part of tensile strength test are tensile strength at break load, percentage elongation at break load and Youngs modulus. From the results, regression analysis had been performed to get the regression equations, which are shown in the tables 3.12, 3.13, 3.14. Then using the equations contour plots and response surfaces were generated for each of them as shown in the figures 3.14 – 3.19.

Table 3.11 Results of Tensile Properties for CaCO3 – HDPE system

| Trial no. | X1 | X2 | Youngs modulus (kg/cm2 ) | Tensile strength @ break load (kg/cm2 ) | Percentage elongation @ break load |

| 1. | 60 | 5 | 1214 | 104 | 80.2 |

| 2. | 60 | 25 | 1157 | 119 | 66.5 |

| 3. | 80 | 5 | 1337 | 159 | 90.5 |

| 4. | 80 | 25 | 1205 | 176 | 174 |

| 5. | 56 | 15 | 840 | 92.5 | 66.4 |

| 6. | 84 | 15 | 1113 | 142 | 193 |

| 7. | 70 | 1 | 1318 | 137 | 52 |

| 8. | 70 | 29 | 1135 | 151 | 87 |

| 9. | 70 | 15 | 1297 | 131 | 68.6 |

| 10. | 70 | 15 | 1297 | 131 | 68.6 |

| 11. | 70 | 15 | 1297 | 131 | 68.6 |

Table 3.12 Estimated Regression Coefficients for Tensile Strength @ break load

| Term | Coef | SE Coef | T | P |

| Constant | 130.882 | 5.054 | 25.895 | 0.000 |

| X1 | 22.891 | 3.111 | 7.358 | 0.001 |

| X2 | 6.515 | 3.111 | 2.094 | 0.090 |

| X1*X1 | -4.690 | 3.735 | -1.256 | 0.265 |

| X2*X2 | 8.958 | 3.735 | 2.399 | 0.062 |

| X1*X2 | 0.500 | 4.378 | 0.114 | 0.914 |

S = 89.52 R-Sq = 80.4% R-Sq (adj) = 60.8%

The regression equation is

Y = 130.882+ 22.891X1 +6.515X2 -4.69X12 +8.958X22 +0.5X1 X2.

Table 3.13 Estimated Regression Coefficients for Tensile Strength Youngs Modulus

| Term | Coef | SE Coef | T | P |

| Constant | 1295.26 | 51.68 | 25.064 | 0.000 |

| X1 | 69.85 | 31.81 | 2.196 | 0.080 |

| X2 | -56.21 | 31.81 | -1.767 | 0.137 |

| X1*X1 | -129.30 | 38.18 | -3.386 | 0.020 |

| X2*X2 | -1.74 | 38.18 | -0.046 | 0.965 |

| X1*X2 | -18.75 | 44.76 | -0.419 | 0.693 |

S = 89.52 R-Sq = 80.4% R-Sq (adj) = 60.8%

The regression equation is

Y = 1295.26+ 69.85X1 -56.21X2 -129.3X12 -1.74X22 -18.75X1 X2.

Table 3.14 Estimated Regression Coefficients for Percentage Elongation

| Term | Coef | SE Coef | T | P |

| Constant | 68.566 | 6.073 | 11.290 | 0 |

| X1 | 37.253 | 3.738 | 9.965 | 0 |

| X2 | 15 | 3.738 | 4.012 | 0.01 |

| X1*X1 | 31.846 | 4.488 | 7.096 | 0.001 |

| X2*X2 | 1.131 | 4.488 | 0.252 | 0.811 |

| X1*X2 | 24.3 | 5.260 | 4.619 | 0.006 |

S = 10.52 R-Sq = 97.41% R-Sq (adj) = 94.9%

The regression equation is

Y = 68.566+ 37.253X1 +15X2 +31.846X12 +1.131X22 +24.3X1 X2.

Fig. 3.14 Contour Plot of tensile strength at break load vs. X2, X1

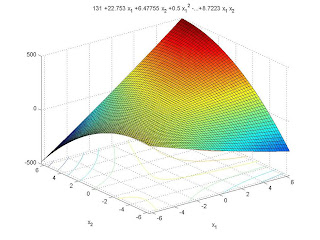

Fig. 3.15 Response surface of tensile strength at break load vs. X2, X1

Fig. 3.16 Plot of Youngs Modulus vs. X1

Fig. 3.17 Response surface of Youngs Modulus vs. X2, X1

Fig. 3.18 Contour plot of Percentage Elongation vs. X2, X1

Fig. 3.19 Response surface of Percentage Elongation vs. X2, X1

1 comment:

Thanks for sharing the information.TensileMill CNC offers small and large,

high speed, machining centers designed to prepare the highest quality flat and round tensile specimens.

Tensile Test Specimen Preparation

Post a Comment