3.4.5 WATER ABSORPTION (ASTM D 570):

The water absorption test was carried out as per the procedure explained in the chapter 2. The results are tabulated as shown in the table 3.18. From the results obtained, we can infer that the water absorption of the calcium carbonate filled HDPE is almost equal to zero percentage.

Table 3.18 Results of water absorption test for calcium carbonate-HDPE system.

| TRIAL | X1 | X2 | INITIAL WEIGHT, (g) | FINAL WEIGHT, (g) | WATER ABSORPTION % |

| 1 | 60 | 5 | 7.604 | 7.606 | 2*10-4 |

| 2 | 60 | 25 | 8.532 | 8.532 | 0 |

| 3 | 80 | 5 | 7.666 | 7.676 | 1.3*10-3 |

| 4 | 80 | 25 | 5.460 | 5.461 | 1.8*10-4 |

| 5 | 56 | 15 | 7.729 | 7.731 | 2.5*10-4 |

| 6 | 84 | 15 | 8.144 | 8.145 | 1.2*10-4 |

| 7 | 70 | 1 | 7.53 | 7.53 | 0 |

| 8 | 70 | 29 | 8.559 | 8.561 | 2.3*10-4 |

| 9 | 70 | 15 | 8.192 | 8.196 | 4.8*10-4 |

| 10 | 70 | 15 | 8.192 | 8.196 | 4.8*10-4 |

| 11 | 70 | 15 | 8.192 | 8.196 | 4.8*10-4 |

4.0 CONCLUSION

An attempt has been made to optimize the amount of filler loading in the HDPE matrix in order to get the desired properties at a comparatively low cost. The optimum mixture is going to be used in the manufacture of blow-molded articles.

The factors, which affect the properties of the filled formulation, were identified and a suitable design of experiments was selected to carry out the study in order to minimize the number of trials, to compensate for the interaction effects of the factors and to obtain maximum information from minimum number of experiments. Response Surface Methodology was applied to the filler optimization.

Compounding trials were carried out at the design points as given in the table and the resultant compound was characterized for mechanical properties such as Tensile Strength, Youngs Modulus, Hardness, Impact Strength, Flexural strength and water absorption. The data obtained from the characterization were used to generate models by linear regression analysis using MINITAB and MATLAB packages. The effect of each factor on the response was tested at 5% level of significance.

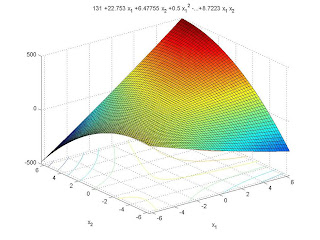

From the tensile strength data linear regression analysis was performed and the following equation was generated

Y = 130.882+ 22.891X1 +6.515X2 -4.69X12 +8.958X22 +0.5X1 X2.

In the above equation the coefficients of X1, X2, X22 are positive and these have a positive effect on the property i.e. the increase in the value of X1, X2, X22 results in a subsequent increase of the property. Though the interaction effect of X1 X2 is present, it is very low when compared to the other coefficients. The coefficient of X12 is negative and it has a negative effect on the property. Using the regression equation, the contour diagrams were generated. A rising ridge type of contour was obtained in which the best ranges for X1 and X2 were found to be 65 – 85 and 0 – 25 respectively.

From the Youngs Modulus data, linear regression analysis was performed and the following equation was generated.

In the above equation only the co –efficient of X1 is positive and this has a positive effect on the property i.e. the increase in the value of X1 results in a subsequent increase of the property. The interaction effect of X1 X2 is also present, it has a negative effect on the property, but it is very low when compared to the other coefficients. The coefficients of other factors are negative and they have a negative effect on the property.

Using the regression equation contour diagrams and response surfaces are generated. A contour diagram of the property vs. factor X1 was generated in which the best value of X1 was found to be between 70 & 75.

From the Percentage Elongation at break data, linear regression analysis was performed and the following equation was generated.

In the above equation the coefficients of all the factors are positive. Hence, all the factors have a positive influence on the Percentage Elongation. Using the regression equation contour diagrams and response surfaces are generated. A stationary ridge type contour diagram was obtained in which the best range for X1 and X2 was found to be between 75 & 85 and 20 & 30 respectively.

From the Flexural Modulus data, linear regression analysis was performed and the following equation was generated.

In the above equation the coefficients of X1 and X2 are positive and these have a positive effect on the property i.e. the increase in the value of X1 results in a subsequent increase of the property. The interaction factor X1 X2, X12 and X22 have a negative effect on the Flexural Modulus. The interaction parameter has a more pronounced effect on the Flexural Modulus. Using the regression equation contour diagrams and response surfaces are generated. A mound shaped contour diagram was obtained in which the best ranges of X1 and X2 were found to be between 65 & 80 and 10 & 20 respectively.

From the Flexural strength data, linear regression analysis was performed and the following equation was generated.

In the above equation the coefficients of X1 and X2 are positive and these have a positive effect on the property i.e. the increase in the value of X1 results in a subsequent increase of the property. The interaction factor X1 X2, X12 and X22 have a negative effect on the Flexural strength. Using the regression equation contour diagrams and response surfaces are generated. A saddle type contour diagram was obtained in which the best ranges of X1 and X2 were found to be between 55 & 63 and 22 & 30 and 0 &15 and 75 & 85 respectively.

From the Shore – A Hardness data, linear regression analysis was performed and the following equation was generated.

In the above equation the coefficients of all the factors were found to be negative and hence all the factors have a negative influence on the hardness. Using the regression equation contour diagrams and response surfaces are generated. A rising ridge shaped contour diagram was obtained in which the best ranges of X1 and X2 were found to be between 68 & 80 and 10 & 20 respectively.

From the Shore – D Hardness data, linear regression analysis was performed and the following equation was generated.

In the above equation the coefficients of all the factors except that one of X2 were found to be negative. Hence, only the factor X2 has a positive influence on the Hardness and all the other factors have a negative influence on the Hardness. Using the regression equation contour diagrams and response surfaces are generated. A rising ridge shaped contour diagram was obtained in which the best ranges of X1 and X2 were found to be between 55 & 68 and 18 & 25 respectively.

From the Charpy Impact data, linear regression analysis was performed and the following equation was generated.

In the above equation, the coefficients of X1, X12 and X1X2 factors were found to be positive and hence all these factors have a positive influence on the Impact. The coefficients of the other terms were negative and hence they have negative effect on the Impact strength. Using the regression equation contour diagrams and response surfaces are generated. A saddle type contour diagram was obtained in which the best ranges of X1 and X2 were found to be between 75 & 85 and 22 & 30 respectively.

From the Izod Impact data, linear regression analysis was performed and the following equation was generated.

In the above equation, the coefficients of X1, X12, X22 and X1X2 factors were found to be positive and hence all these factors have a positive influence on the Impact. The coefficients of the other terms were negative and hence they have negative effect on the Impact strength. Using the regression equation contour diagrams and response surfaces are generated. A saddle type contour diagram was obtained in which the best ranges of X1 and X2 were found to be between 77 & 85 and 25 & 30 respectively.

From the Percentage Elongation at peak data, linear regression analysis was performed and the following equation was generated.

In the above equation, the coefficients of X1, X2, X1 X2 factors are positive. Hence, all these factors have a positive influence on the Percentage Elongation at peak. The coefficients of all the other factors are negative and hence they have a negative effect on the elongation. Using the regression equation contour diagrams and response surfaces are generated. A contour diagram vs. the factor X1 generated and the best value of the X1 was found to be between 60 & 65.

The equations and diagrams that are generated using MINITAB can be used with an accuracy of 90 % in all cases.

The contour plots obtained individual properties were overlaid to overlaid contour plots in order to get simultaneous optimization of the various properties of interest. The contour plots of all the Tensile properties (Tensile strength, Youngs Modulus, and Percentage Elongation at break) were optimized simultaneously and it was found that the desired properties could be obtained at any combination in the white coloured region of the plot.

The individual contour plots of the Flexural properties (Flexural Modulus, Flexural strength, and Percentage Elongation @ peak ) were also overlaid and from the over laid contour plot it was found that the desired properties could be obtained at any combination within the optimized region indicated by the white coloured region in the contour plot.